About making clothing, looking for ideal material and fabric is the first step in the creation of impressive clothing. Itto UNSAI and Bizen Ichigo produced by TAKEYARI CO. are two fabrics I fell in love with.

TAKEYARI is an old-established weaver in Kurashiki, Okayama. The company is known for canvas and bag materials, but it also manufactures wonderful fabric suitable for clothing. And this is the one I had long searched for.

The history of TAKEYARI

Production began following the marriage of Ishigoro Takeyari, a farmer and trader in the Kojima region, and Ume, an accomplished weaver, and this marked the beginning of Takeyari’s history. Ume, who was known locally as an excellent weaver, began to receive orders for kakuobi(stiff sashes for men) and soles for tabi (a type of Japanese sock)from cotton merchants that had heard of her requtation. The “TAKEYARI Textile Factory” was established at its current location.

The “TAKEYARI Textile Factory” was established at its current location. Kazuo, the third generation , introduced picanol shuttle looms made in Belgium, and this allowed the company to produce extra-thick No.1~3 canvas, which other factories were unable to weave. The Company name changed from TAKETARI Textile Co.Ltd. to TAKEYARI Co.,Ltd. Currently, the company is developing three personal brands that make use of TAKEYARI’s characteristics as a weaver: “TAKEYARI since 1888,” “UNDER CANVAS” and “ITTO UNSAI.”

What is canvas of “TAKEYARI”

Kurashiki City in Okayama Prefecture is a major production area for canvas, and the area occupies 70% of the entire domestic canvas production share. The textile and cotton spinning industries developed in the area due to the popularity of cultivating cotton here from the medieval up to the Edo period. Canvas is a type of fabric made by twisting together of cotton and hemp, which is then woven in a plain weave. As canvas weaves are very tight, the fabric is durable and water-resistant while still retaining excellent breathability. Due to these qualities, the fabric has long been used for ship sails, horse riding gear, school bags, etc. TAKETARI manufactures all grades of canvas from No.1 to No.11. Slowly weaving the fabric over a long period of time using picanol shuttle looms made in Belgium, few of which are still in existence, results in fine-textured canvas. In particular, No.1~3 canvas possess a thickness that would be difficult to achieve elsewhere. The canvas is tougher and firmer than regular canvas as it created by densely weaving together thick strands.

Itto UNSAI

UNSAI weaving originated in the Bizen area of Okayama, and the fabric was used for Jika-tabi (outdoor footwear) soles to protect the feet of workers. Pushed by mass and efficiency-focused productions, UNSAI weaving was slowly forgotten. This UNSAI weaving has been rediscovered in the modern era as Itto UNSAI. Using the Belgian shuttle loom, PICANOL, which has become a rare machine, abundant time is spentto make an outstanding fabric with rich texture and appearance by unimaginably repeating the weaving until the limit of its density. Textile with single warp and weft threads (single spinned thread).

BizenIchigo

This fabric was developed sometime between 1955 and 1965, after WWII, in the Bizen area to be used for making school uniform. It was created in cooperation of yarn makers, textile makers, dye factories and school uniform makers in Okayama getting together to produce “beautiful fabric for children that has class and that can stand repeated washing,” and bringing out all their wisdom and passion, when, at the time, there was a stark lack of resources. Textiles created with twisted double threads used for warp and weft. Combed yarn (high-grade fine-count cotton thread made by removing short fibers and arranging only long fibers in parallel) is used for warp for glossy luster on the surface and a soft feel on the skin, a sensation that has never been experienced with other fabric.

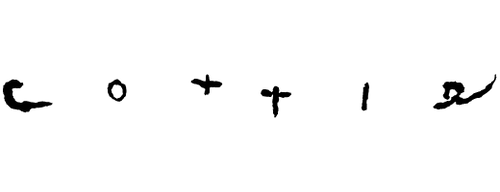

COTTLE uses Itto UNSAI as base to create Kibata (gray fabric) with cotton for warp and linen for weft as an original fabric. Fabric is made using the softness of cotton and the natural nep of linen. This has become a representation of our identity that expresses our creative urge with the PICANOL shuttle loom, like growing a plant that has just sprouted or the canvas for an artist at work. (Kibata is a fabric before dyeing)

After WWII, prosperity of Kurashiki, Okayama began as the production center for tabi socks, which is followed by the production of work clothes and school uniforms, and the city is well known as the birthplace of Japanese denim jeans. From about 1960, the Kojima area in Kurashiki City flourished through the production of denim jeans. Jeans originated as clothing for workers in the US. Indigo color added durability and richness to the fabric and metal rivets for reinforcing the pocket opening and others have been developed.

Denim jeans came to Japan from the US. And I feel the same empathy in the fabric created by TAKEYARI. In the history of Bizen Ichigo and Itto UNSAI, there exists a long tradition of weaving domestic canvas fabric, and experience, pursuit and ambition of many craftsmen who sought to make improvements considering the people who wear them. As with denim jeans, the beauty of our fabric will capture you with its durability and texture that becomes better as time passes and produces a comfortable feel on the skin.We aim to hand down the philosophy to the people of next generation by communicating passion of creators for manufacturing, and the environment and history of the production area through the products we create.